Centerpoint

Gary Biorefinery & Two Regional Feedstock Processing Facilities

Key Facts

$800 Million

Economic Investment

200

Permanent Jobs

700,000

Tons of Waste Diverted from Regional Landfills Annually

31 Million Gallons

of Sustainable Aviation Fuel Produced Annually

2026

Expected Operations

What is Sustainable Aviation Fuel (SAF)?

Sustainable aviation fuel is an alternative to traditional jet fuel that is made from renewable resources (such as biomass and household garbage) rather than crude oil. It can significantly reduce greenhouse gas emissions from flying, enabling airlines to reduce their contribution to climate change.

Gary Biorefinery Facts

- Economic Investment: $600+ million

- Direct Employment: 130 full-time operational jobs and 1,000 construction jobs

- Indirect Employment: Numerous jobs supporting the facility including technical trades, logistics and supply chain

- Average Wage: $30 per hour, plus above industry average employee benefits

- Timeline: Expected commercial operations in 2026

- Waste Removed: Approximately 700,000 tons per year of waste diverted from regional landfills

- Fuel Produced: Approximately 31 million gallons of sustainable aviation fuel produced each year

Gary Biorefinery Key Points

- Fulcrum’s process includes gasification and Fischer-Tropsch technologies that were created in the early 20th century and have been used for decades in a variety of applications.

- Fulcrum’s process does not burn or incinerate household garbage. The biorefinery IS NOT a waste incinerator. It will use a process known as gasification that does not burn or incinerate material. Gasification uses a high temperature and low oxygen environment to break the feedstock down into basic molecules, like hydrogen and carbon. The resulting gas – known as syngas – is then converted into fuel.

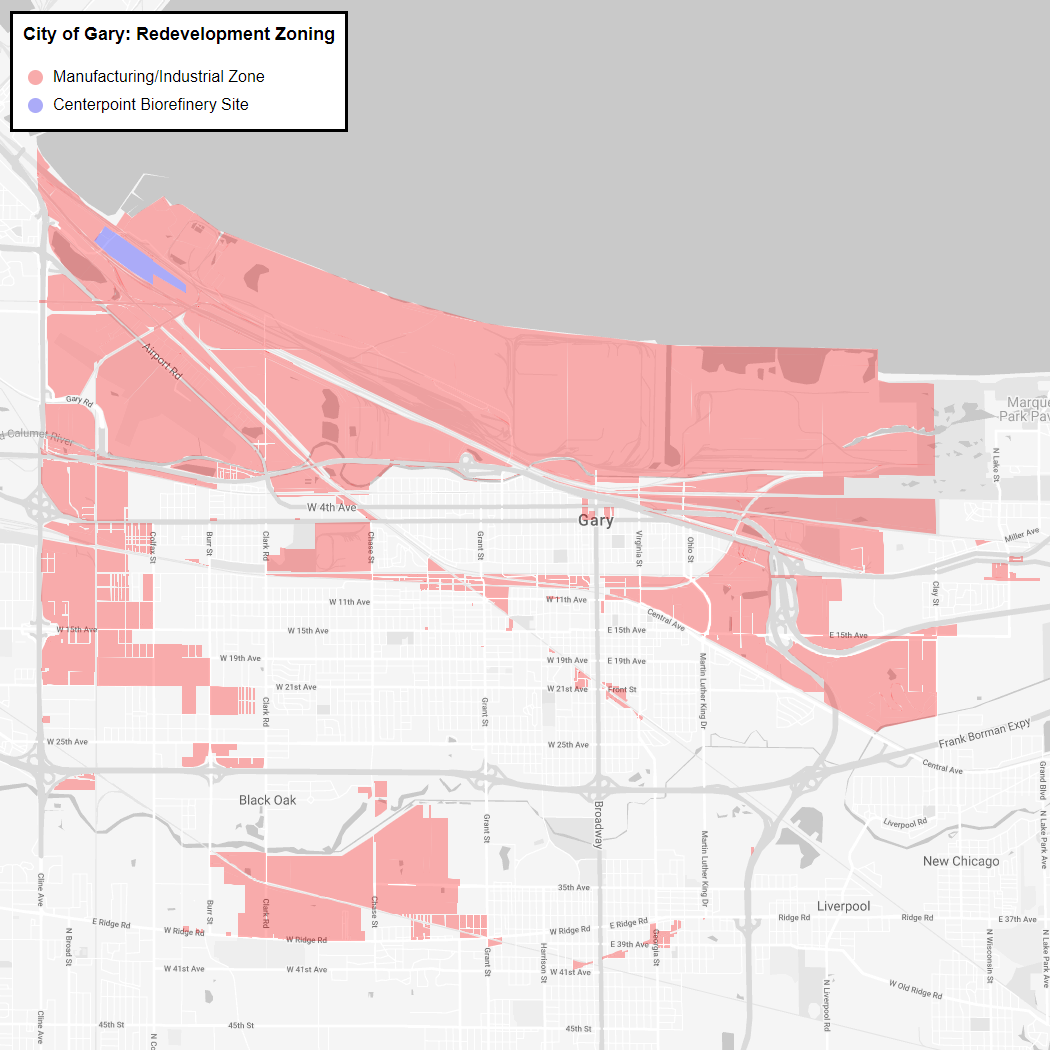

- Household garbage will be processed into what is known as a feedstock for Centerpoint at two processing facilities located outside of Gary. Household garbage from Chicago and other municipalities WILL NOT be brought into Gary.

- Centerpoint’s feedstock contains some plastic because it is in household garbage and is otherwise hard to avoid. Fulcrum has a strong incentive to limit the amount of plastic in the feedstock and is investigating several ways of doing this. The best way to avoid plastic is to not produce it and Fulcrum supports measures that reduce plastic waste including consumer recycling and the banning of single use plastics.

How It Works

Fulcrum has developed an innovative process that transforms waste that would otherwise be sent to a landfill into low-cost, low-carbon renewable transportation fuels while generating well-paying jobs. Fulcrum's first commercial facility near Reno, Nevada - the Sierra BioFuels Plant - began operations in 2022 and successfully produced low-carbon synthetic crude oil from landfill waste in December 2022.

Environment

As a company dedicated to creating fuels that will help our planet, address the growing impacts of climate change and reduce waste in our communities, the environmental impact of our clean energy plants is of great importance to us.

Gary Biorefinery

- Air. Operating under an air permit from the Indiana Department of Environmental Management (IDEM), the biorefinery’s air emissions will largely be the combustion of natural gas for processes like steam production. The biorefinery’s projected emissions are all under “major source” thresholds, which are far more stringent in Lake County than national EPA standards. The biorefinery received its minor source air permit from IDEM on August 16, 2022. Feedstock produced by the FPFs will be transported to the biorefinery in trucks using designated heavy vehicle routes. To eliminate air emissions and reduce noise from trucks, Fulcrum is investigating the feasibility of using electric semis for feedstock transportation.

- Water. The biorefinery will not directly discharge anything into Lake Michigan or any other water source. Wastewater will be pre-treated onsite before being sent to the Gary Sanitary District (GSD) for further treatment. The biorefinery will receive recycled water from GSD to use instead of fresh water.

- Land. With its biorefinery location, Fulcrum will be re-purposing a vacant Brownfield site. The site has approximately 2.3 acres of wetlands (not dune or swale habitat) located on the eastern end of the property of which Fulcrum intends to not disturb.

Timeline

Since beginning the Centerpoint planning process in 2018, Fulcrum has continued the process of permitting, engineering and other pre-construction related activities. Future project timelines include:

- Pre-Construction (Permitting & Engineering): 2021 - 2023

- Construction: 2024 - 2025

- Operations Commence: 2026

Project Contact

Dana Wesolek, PE

Senior Developer – Centerpoint

dwesolek@fulcrum-bioenergy.com