Frequently Asked Questions

Need to Know

Q: What is Fulcrum Centerpoint?

A: Fulcrum Centerpoint will convert one of our nation’s most abundant resources – household garbage – into sustainable aviation fuel at a facility located in Gary, Indiana. By doing so, Centerpoint will help reduce environmental problems associated with landfills, whilst reducing the airline industry’s dependance on fossil fuel and contribution to climate change.

Q: What is Sustainable Aviation Fuel?

A: Sustainable aviation fuel is an alternative to traditional jet fuel that is made from renewable resources (such as biomass and household garbage) rather than crude oil. It can significantly reduce greenhouse gas emissions from flying, enabling airlines to reduce their contribution to climate change.

Q: What are the benefits for Gary?

A: Centerpoint represents a $600 million dollar investment in Gary. It will create 130 full-time permanent jobs and 1,000 jobs during construction. Fulcrum is committed to hiring local residents and is working with Ivy Tech Community College to provide skills training programs. Centerpoint will also facilitate a $10 million contribution to help fund the demolition of abandoned buildings in Gary and the project will also generate valuable property tax revenue.

Q: Will Centerpoint burn or incinerate household garbage?

A: No. Fulcrum’s process does not burn or incinerate household garbage. Centerpoint IS NOT a waste incinerator. It will use a process known as gasification that does not burn or incinerate material.

Q: Will trash or household garbage be brought into Gary?

A: No. Household garbage will be processed into what is known as a feedstock for Centerpoint at two processing facilities located outside of Gary. Household garbage from Chicago and other municipalities will not be brought into Gary.

FAQs

Q: Who is Fulcrum BioEnergy?

A: Fulcrum BioEnergy is a developer of projects that will produce sustainable aviation fuel from one of our nation’s most abundant resources – household garbage. Beginning with the Fulcrum Sierra BioFuels in Nevada, Fulcrum is advancing a growth program of projects in the U.S. that will produce approximately 400 million gallons annually. Fulcrum Centerpoint[1] will be Fulcrum BioEnergy’s next project located in Gary, Indiana.

Q: Where will Centerpoint be located?

A: Centerpoint will be in the Buffington Harbor area of Gary, Indiana, on a vacant industrial zoned property that is surrounded by other industrial uses. Centerpoint will be supported by two feedstock processing facilities that will be located outside of Gary, which will process household garbage into a feedstock that Centerpoint will then convert into sustainable aviation fuel.

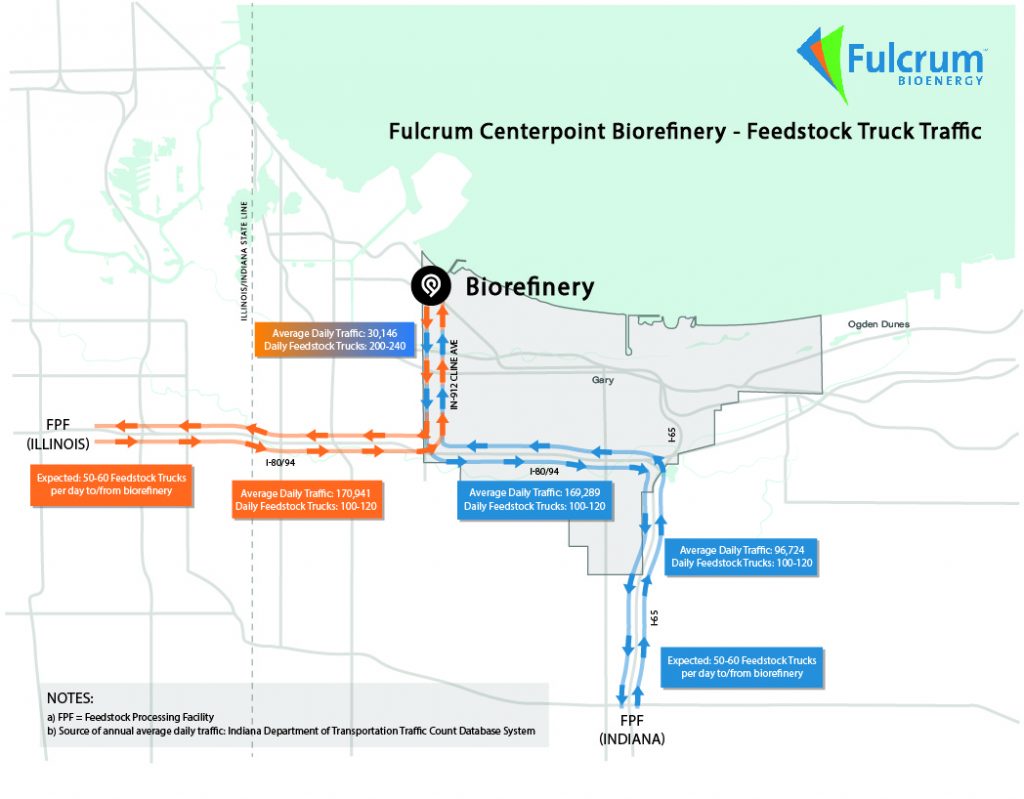

Q Where will the feedstock processing facilities be located?

A: One facility will be located on the I-90 corridor west of Chicago and second facility will be located on the I-65 corridor in northwest Indiana.

Q: How will feedstock be transported?

A: Feedstock produced at the feedstock processing facilities will be transported to Centerpoint in trucks using heavy vehicle routes via I-90, Cline Avenue (IN-912) and Buffington Harbor Drive. Trucks will not use any residential streets. At full production, an estimated 90 trucks per day (Monday to Friday) will deliver feedstock to Centerpoint. To reduce impacts from trucks, Fulcrum is investigating the feasibility of using electric semis for feedstock transportation.

Q: How will sustainable aviation fuel be transported?

A: The sustainable aviation fuel produced at Centerpoint will be loaded into rail tank cars and moved offsite via rail to their destinations. At full production, fuel produced at the biorefinery will fill four to five rail cars each day.

Q: Who will use the sustainable aviation fuel produced by Centerpoint?

A: United Airlines and Cathay Pacific will purchase the sustainable aviation fuel produced by Centerpoint and will be used at airports of their choosing.

Q: When is Centerpoint expected to be operational?

A: Centerpoint is expected begin operations in 2026.

Q: What is the status of Fulcrum’s Nevada plant?

A: Fulcrum Sierra BioFuels began operations in 2022 and is now producing low carbon transportation fuel. Read the media release.

Q: How will Centerpoint be paid for?

A: The Indiana Finance Authority has awarded Fulcrum $500 million in municipal bond allocation to finance the project. This is not a grant or financial contribution from the State of Indiana. It represents an approval for Fulcrum to sell up to $500 million in bonds to investors, which provides the debt for construction and the repayment of which sits entirely with Fulcrum. The remaining capital required to build Centerpoint will come from Fulcrum and its investors.

Q: How will Fulcrum ensure jobs are available for Gary residents?

A: Fulcrum has made commitments to prioritize hiring of Gary residents for operations and for construction. Fulcrum is working with Ivy Tech Community College to facilitate training and skills development for Gary residents to ensure there is a training and skills development pathway for Gary residents.

Q: What are the environmental benefits from using household garbage?

A: Centerpoint and its feedstock processing facilities will divert household garbage from landfills in the region. This not only helps to reduce methane emissions from landfills, but it also helps address several other environmental problems and their impact on local communities, including odor, litter, contamination, and landfill expansions.

Q: What are the environmental benefits of Fulcrum’s sustainable aviation fuel?

A: Because of reduced methane emissions from landfill and the renewable material in household garbage, the sustainable aviation fuel produced by Fulcrum will reduce greenhouse gas emissions by more than 80 percent compared to traditional jet fuel.[2]

Q: Why is there plastic in the feedstock that Centerpoint will convert into sustainable aviation fuel?

A: Centerpoint’s feedstock contains some plastic because it is in household garbage and is otherwise hard to avoid. Fulcrum has a strong incentive to limit the amount of plastic in the feedstock and is investigating several ways of doing this. The best way to avoid plastic is to not produce it and Fulcrum supports measures that reduce plastic waste including consumer recycling and the banning of single use plastics.

Q: What is the status of the site that Centerpoint will be located on?

A: Centerpoint will be built on an industrial property that was once a cement manufacturing plant. The site has sat vacant for over 20 years and is surrounded by industrial uses, including railways and manufacturing facilities. Fulcrum will demolish the abandoned buildings and structures that remain on the property and clean it up prior to commencing construction.

Q: What are the permitting and regulatory requirements for Centerpoint?

A: The Indiana Department of Environmental Management (IDEM) and the City of Gary are the primary permitting and regulatory authorities. IDEM is responsible for enforcing all EPA standards and requirements. Centerpoint received a minor source air permit from IDEM on August 16, 2022 and is the process of obtaining several permits from the City of Gary. A full set of FAQs regarding Fulcrum's Air Permit is available here: Air Permit FAQs. More information on current permitting status is available under the Permitting section on the Centerpoint Environment page.

Q: How will air emissions be minimized and controlled?

A: Centerpoint will use several important pieces of equipment to minimize air emissions. While Centerpoint will have air emissions it will be a minor source, which is reflected in the air permit issued by IDEM.

Q: How will wastewater be managed?

A: Wastewater from Centerpoint will be pre-treated onsite before being sent to the Gary Sanitary District (GSD) wastewater treatment plant for further treatment. Centerpoint will also receive recycled water from GSD for its process (instead of fresh water). This should result in a decrease in the amount of treated wastewater discharged from the GSD treatment plant into local waterways.

Q: Is there any connection with Lake Michigan?

A: Centerpoint will not directly discharge anything into Lake Michigan or any other water source. Stormwater from facility will be collected and held in a stormwater pond on site and Centerpoint will have a stormwater management plan and stormwater permit from the City of Gary.

[1] Fulcrum Centerpoint has no relationship with Centerpoint Energy

[2] This is measured on a lifecycle basis and these calculations are done in accordance with EPA standards and then certified by the EPA and other state regulatory authorities.